It’s clear we’re all in a very unique situation right now. While certain industries like retail, catering, and travel/tourism are suffering tremendously, knowledge workers – in a whole variety of sectors – are, for the most part, able to better weather the storm.

This is partly because many companies have already adopted cloud-based platforms and have made a relatively painless transition to operating remotely – despite the many distractions and complications that come from working at home during an international lockdown.

However, many other businesses – such as manufacturing – which could remain operational with the right IT infrastructure in place (but currently don’t) have a unique opportunity to rethink how they can better prepare their businesses for digital acceleration when the risk of COVID-19 subsides.

New Challenges, New Processes

The first step in determining the need for digital services is to take a good hard look at current business processes and the dependencies from external sources

What are the immediate challenges? Are they adaptable? Are they sustainable in the long term? What can we do right now that will put us in an advantageous position moving forward?

While employees have to keep physical distance from each other right now, if a situation like this happened again, how could your factory remain operational with the bare minimum of on-site staff?

Sure, these are tough questions for manufacturers to have to ask, but they highlight the need for more agility and leaner processes in daily operations – and for better alignment with office teams. If it feels as though companies are being forced to redress existing and well as immediate concerns, you’re absolutely right.

Sometimes it takes an unforeseen situation to truly make us think about what’s necessary and what’s not. Often we’re so caught up in maintaining momentum, there’s little time to go back to the drawing board and document the way forward – which needs to happen before any investment in the necessary IT solutions can be made.

More Agile Activity

For the most part, any business looking to accelerate its digital transformation will look to the cloud right away. As well as being secure and flexible, one of the main benefits of cloud solutions is that they’re scalable. They can be configured on a pay-per-usage basis – meaning businesses with fluctuating workforces can dial up or down the capacity they need when they need it. Of course connectivity and bandwidth is under pressure when everybody works online, but again, a contingency plan is needed.

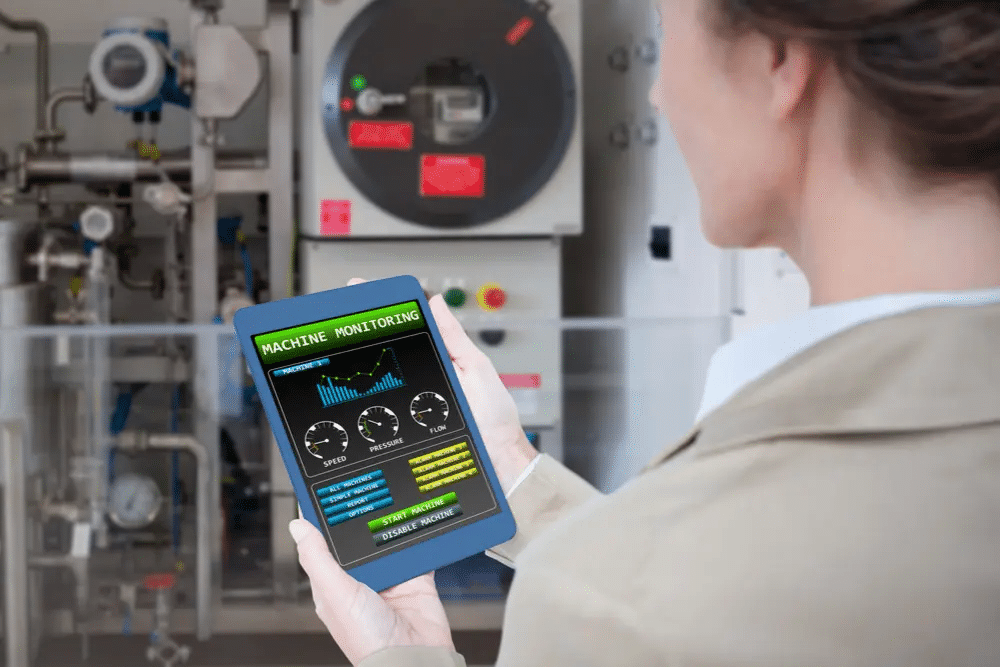

This also applies to smart manufacturing. Production processes need to be adjusted to. For example, factories may need to increase the number of IoT sensors they’re using to ensure that they get accurate operations data – which also helps with things like predictive maintenance; meaning that replacement parts can be ordered and will arrive in stock well before they need replacing.

Automation, AI (Artificial Intelligence), and machine learning are all important too. The ability to leverage and act on real-time insights collected from big data, systematise processes, and link them all together in a harmonised way is one of the true advantages of smart manufacturing.

Consumer Demands & Core Business Needs

All things considered, despite the current crisis, we are still very much in a consumer demand-driven culture where products are needed. However, the way in which these needs can be met is changing to be smarter and more flexible. Where we outsource to, and procure from, may need to be reviewed in line with travel restrictions.

Manufacturers are learning to do more with less. This means they need to invest in better technology and tools, and relies on having more technically capable staff who can optimise processes and performance. It also means that more experienced employees with industry and process experience can help define the value the company needs from the new technology – in line with core business needs.

The moment companies start to think differently – the more they adapt to change – the better their outlook for when the situation begins to improve. Having better scalability and the tech to do achieve this will help propel businesses forward when some sort of normality resumes.

Interested in how your organisation can get started with smart processes and IoT? Book now your free consultation or subscribe hassle-free for regular updates.